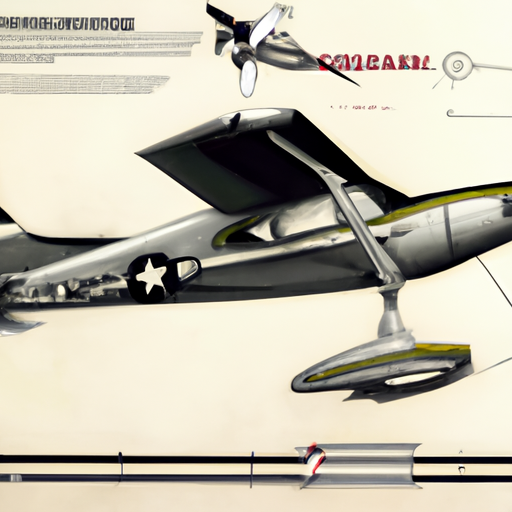

Do you love airplanes? Have you ever wondered how to draw your favorite aircraft? Well, you’re in luck! In this article, we’re going to talk about drawing a Cessna, one of the most popular aircraft in the world. Whether you’re an aviation enthusiast or just enjoy doodling, we’ll show you step-by-step how to create your very own Cessna drawing. So, let’s get started and unlock your inner artist!

Drawing a Cessna may seem intimidating at first, but with a little practice, you’ll be able to capture its sleek lines and distinctive shape. In this drawing tutorial, we’ll break it down into simple steps, making it easy for you to follow along. From outlining the fuselage to adding wings, tail, and details, we’ll guide you through the process. By the end of this article, you’ll have a detailed Cessna drawing that you can be proud of. So, stay tuned and get ready to take your artwork to new heights!

History of Cessna Aircraft

Cessna Aircraft is a renowned name in the aviation industry, known particularly for its high quality and reliable aircraft. The company was founded in 1927 by Clyde Cessna, a pioneer in aviation.

The founding of Cessna Aircraft

Clyde Cessna first gained prominence as a designer and builder of racing and sport aircraft in the early 1900s. His passion for flying and innovative aircraft designs led him to establish Cessna Aircraft Company in Wichita, Kansas. The initial aim of the company was to cater to the growing demand for small, recreational aircraft.

Early aircraft designs

In its early years, Cessna Aircraft focused on designing and manufacturing biplanes, which were widely used for personal and commercial purposes. The company’s commitment to quality and attention to detail quickly gained it a reputation for producing reliable and efficient aircraft.

Introduction of Cessna Drawing

As Cessna Aircraft expanded its product range and started designing more complex aircraft, the need for accurate and detailed drawings became evident. Cessna Drawing was introduced as a standardized system to document and communicate the various aspects of aircraft design and manufacturing. This system played a crucial role in ensuring consistency and precision throughout the production process.

Overview of Cessna Drawing

Definition and purpose of Cessna Drawing

Cessna Drawing can be defined as a set of technical illustrations, diagrams, and specifications that provide a comprehensive representation of an aircraft and its components. The primary purpose of Cessna Drawing is to communicate precise design specifications to engineers, manufacturers, and technicians involved in the production and maintenance of Cessna aircraft.

Importance of accurate Cessna Drawings

Accurate Cessna Drawings are paramount to the success of an aircraft manufacturing process. They serve as the foundation for creating parts, assembling aircraft components, and ensuring the aircraft’s functionality and safety. Each drawing contains vital information, such as dimensions, tolerances, materials, and manufacturing processes, which must be followed meticulously to achieve the desired outcome.

Application of Cessna Drawing in aircraft manufacturing

Cessna Drawing is an integral part of the aircraft manufacturing process. It guides engineers, manufacturers, and technicians in the production and assembly of various aircraft components. These drawings serve as a blueprint, ensuring efficient and precise construction of the aircraft. They also play a crucial role in maintaining consistency and uniformity across different production stages and aircraft models.

Types of Cessna Drawings

Assembly drawings

Assembly drawings provide a detailed representation of how various components of an aircraft are assembled together. These drawings show the location, orientation, and interconnection of different parts, facilitating the proper alignment and fitment during the assembly process.

Detail drawings

Detail drawings provide a close-up view of individual parts and components of an aircraft. They depict the specific dimensions, tolerances, and material specifications required for manufacturing each part. Detail drawings are crucial for ensuring accurate and precise production of intricate components.

Installation drawings

Installation drawings depict the process and position of installing various components in an aircraft. These drawings show the arrangement and connection of different parts, such as avionics, control systems, and cabin interiors, ensuring proper installation and functionality.

Circuit diagrams

Circuit diagrams illustrate the electrical wiring and connections within an aircraft. These diagrams are vital for understanding the electrical systems, ensuring correct wiring and troubleshooting any electrical issues that may arise.

Wiring diagrams

Wiring diagrams provide a detailed representation of the electrical wiring layout of an aircraft. These diagrams depict the routing, connection, and identification of electrical wires and cables, facilitating accurate installation and timely maintenance of the aircraft’s electrical systems.

Components of Cessna Drawing

Title block and identification

Every Cessna Drawing starts with a title block, located in the bottom right corner, containing essential information such as the drawing number, revision level, and identification of the part or assembly depicted in the drawing. This information ensures proper identification and organization of the drawings.

Parts list and materials

Cessna Drawings include a parts list that specifies each component required for the assembly of an aircraft. This list provides information such as part numbers, materials, and quantities, enabling efficient procurement and manufacturing processes.

Geometric dimensioning and tolerancing

Geometric dimensioning and tolerancing (GD&T) is a crucial component of Cessna Drawings. It specifies the dimensions, tolerances, and geometric features of each part, ensuring accurate manufacturing and proper fitment during assembly. GD&T helps maintain the desired quality standards and ensures the functionality and safety of the aircraft.

Symbols and annotations

Symbols and annotations are used extensively in Cessna Drawings to provide additional information and clarify specific details. These symbols can represent various features, such as fasteners, surface finishes, and mating parts. Annotations include notes and callouts, explaining critical aspects that may need attention during manufacturing or assembly.

Software Tools for Cessna Drawing

Computer-aided design (CAD) software

CAD software has revolutionized the field of aircraft design and manufacturing, including Cessna Drawing. CAD software allows engineers to create accurate and detailed 3D models of aircraft components, which can be used to generate various views and sections required in Cessna Drawings. CAD software provides advanced tools for drafting, dimensioning, and annotation, enabling efficient and precise creation of Cessna Drawings.

Computer-aided drafting (CAD) software

CAD software assists in creating two-dimensional (2D) representations of the aircraft components, which are essential for generating detailed Cessna Drawings. CAD software simplifies the process of drafting, enabling engineers to create precise and standardized drawings efficiently.

Simulation and analysis tools

Simulation and analysis tools are used in conjunction with Cessna Drawing to evaluate the performance and safety of aircraft components. These tools help engineers simulate real-world scenarios, test the functionality of the components, and identify any potential design flaws or weaknesses.

Creating a Cessna Drawing

Understanding the specifications and requirements

Before starting the Cessna Drawing process, it is crucial to thoroughly understand the specifications and requirements of the aircraft component or assembly being drafted. This involves studying design documents, technical specifications, and any relevant industry standards.

Gathering necessary data and measurements

Accurate data and measurements are essential for creating precise Cessna Drawings. Engineers must gather all the necessary information about the component or assembly, including dimensions, tolerances, and material specifications. This data can be obtained from various sources, such as design documents, engineering calculations, and physical measurements.

Sketching and initial layout

Once the data is gathered, engineers often start by sketching the component or assembly on paper to establish the overall layout and design. This helps in visualizing the final product and identifying any potential issues or improvements before moving on to the CAD software.

Using CAD software for detailed design

After the initial sketching phase, engineers transfer the design into CAD software for detailed drafting. They create accurate and detailed 2D views and sections of the component or assembly, incorporating the required dimensions, tolerances, annotations, and symbols. CAD software also allows for easy modification and revision of the drawings as needed.

Review and revision process

Once the Cessna Drawing is complete, it undergoes a thorough review process to ensure accuracy and compliance with design specifications. Engineers, designers, and other stakeholders carefully examine the drawings for any errors, omissions, or inconsistencies. If any issues are identified, revisions are made accordingly until a final, error-free drawing is obtained.

Challenges in Cessna Drawing

Maintaining accuracy and precision

One of the biggest challenges in Cessna Drawing is maintaining accuracy and precision throughout the drawing process. Even minor errors or inconsistencies can have severe consequences during aircraft manufacturing and assembly, leading to faulty components and compromised safety.

Managing complexity of aircraft systems

Aircraft systems are highly complex, with numerous interconnected components and subsystems. Capturing the intricacies of these systems in Cessna Drawings requires a deep understanding of the aircraft design and a meticulous approach to detailing. Managing this complexity and ensuring that all relevant details are accurately represented is a significant challenge in Cessna Drawing.

Integrating latest technology advancements

The aviation industry is continuously evolving, with new technologies and innovations being introduced regularly. Keeping up with these advancements and incorporating them into Cessna Drawings can be a challenge. Engineers and designers must stay updated on the latest industry trends and ensure that their drawings reflect the latest technology and design practices.

Training and Skill Requirements

Understanding aircraft design principles

Creating accurate and effective Cessna Drawings requires a solid understanding of aircraft design principles and concepts. Knowledge of aerodynamics, material science, and structural mechanics is essential for producing drawings that meet the functional and safety requirements of the aircraft.

Proficiency in CAD software

Proficiency in CAD software is crucial for creating detailed and accurate Cessna Drawings. Engineers and designers must be well-versed in using CAD software to generate 2D and 3D representations of aircraft components, apply appropriate dimensions and annotations, and navigate the software efficiently.

Knowledge of industry standards and regulations

A good understanding of industry standards and regulations is necessary for creating Cessna Drawings that comply with safety and quality requirements. Engineers must stay updated on the latest aviation standards and regulations, such as those outlined by the Federal Aviation Administration (FAA), to ensure their drawings meet the necessary criteria.

Attention to detail and problem-solving skills

Creating Cessna Drawings requires a keen eye for detail and excellent problem-solving skills. Engineers must be able to identify potential design issues, anticipate manufacturability challenges, and propose solutions to overcome these obstacles. Attention to detail is crucial for ensuring accuracy and consistency in the drawings.

Role of Cessna Drawing in Aircraft Safety

Ensuring proper assembly and installation

Accurate Cessna Drawings play a critical role in ensuring proper assembly and installation of aircraft components. The drawings provide technicians with precise instructions on how to correctly align, fit, and secure various parts, reducing the risk of assembly errors that could compromise the aircraft’s safety and functionality.

Facilitating maintenance and repairs

Cessna Drawings also play a significant role in aircraft maintenance and repair operations. These drawings provide maintenance technicians with the necessary information to diagnose and troubleshoot issues, properly disassemble and reassemble components, and follow recommended maintenance procedures.

Supporting aircraft certification processes

Accurate and comprehensive Cessna Drawings are essential for aircraft certification processes. Aviation authorities, such as the FAA, rely on these drawings to evaluate the aircraft’s compliance with safety regulations and design standards. Thorough and accurate drawings expedite the certification process and ensure that the aircraft meets all necessary requirements.

Conclusion

Accurate and detailed Cessna Drawings are paramount to the success of aircraft manufacturing and maintenance processes. They provide engineers, manufacturers, and technicians with precise instructions and specifications, allowing for the efficient production, assembly, and maintenance of Cessna aircraft. As technology advances and aircraft designs become more complex, the importance of accurate Cessna Drawings will only continue to grow. By ensuring consistency, accuracy, and safety, Cessna Drawings contribute significantly to the overall success and reliability of Cessna aircraft.

Leave a Reply